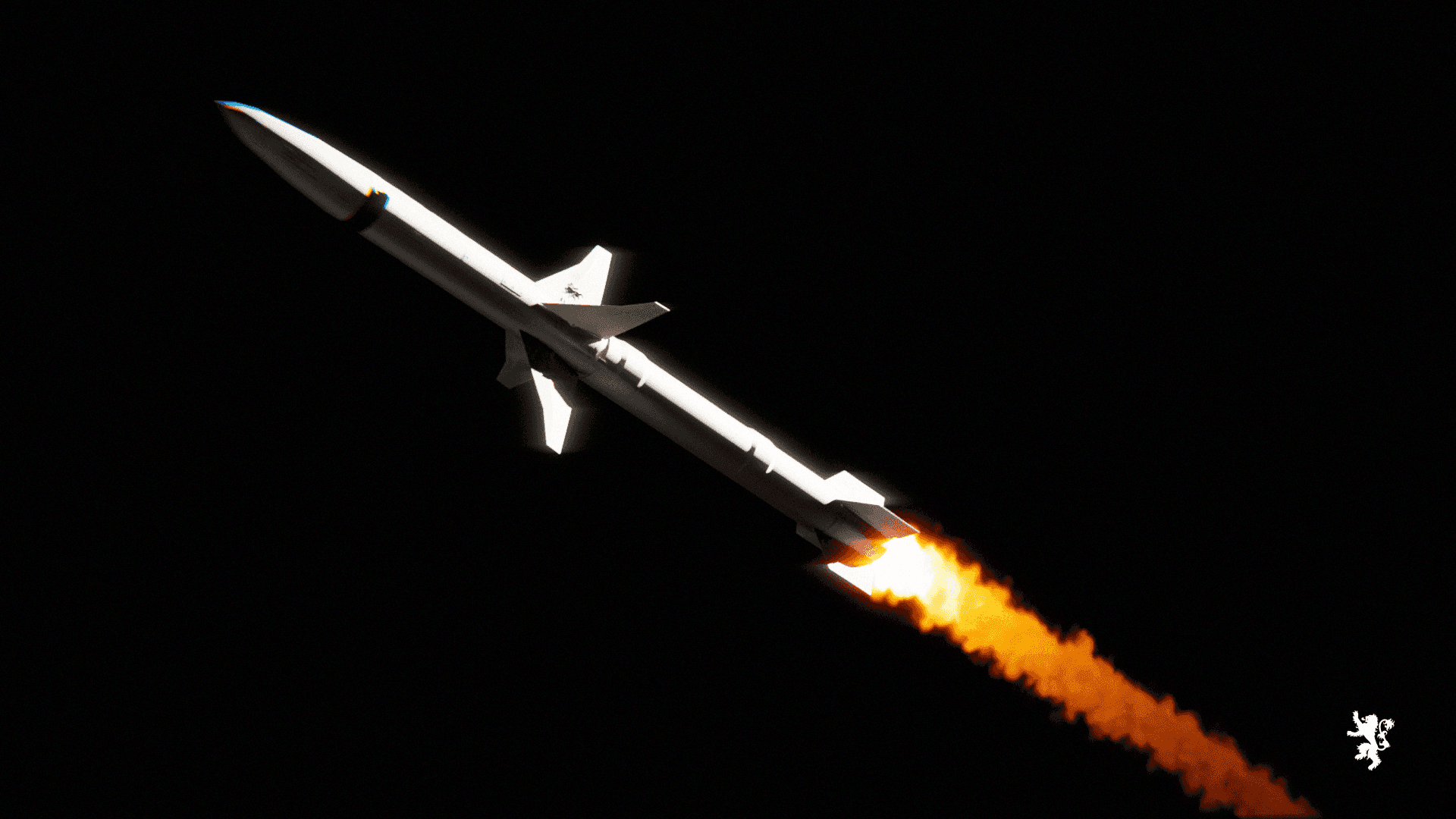

3D Printing Rockets for in-sito resource utilization? The future of space exploration.

The Next Frontier: 3D Printing in Aerospace and Rocketry 🚀

Lyon Industries delves deep into the transformative impact of 3D printing and additive manufacturing on aerospace and rocketry. This exploration not only uncovers the current state of play but also charts a course for the future, providing an enlightening journey through innovation and beyond.

Introduction: The Dawn of a New Era

In the heart of innovation, where the sky meets the stars, Lyon Industries stands at the forefront of a revolution. The advent of 3D printing and additive manufacturing has ushered in a new era for aerospace and rocketry, transforming traditional paradigms and challenging the limits of what's possible.

The Current State: Achievements and Milestones

🛠 Innovations in Manufacturing

- Complex Components: The ability to produce complex geometries that were previously impossible or prohibitively expensive.

- Material Efficiency: Significant reductions in material waste compared to traditional subtractive manufacturing processes.

- Speed: Accelerated production times, enabling faster prototyping and iteration.

🌍 Case Studies: From Earth to Orbit

- SpaceX: Pioneering the use of 3D-printed parts in rockets, SpaceX has incorporated 3D printing into engines, fuselage components, and more, demonstrating the technology's versatility and reliability.

- NASA: Leveraging additive manufacturing for the creation of parts that can withstand the extreme conditions of space, NASA's applications range from satellite components to elements of the Mars rover.

The Impact: Reshaping Aerospace Engineering

🚀 Reduced Costs, Increased Accessibility

3D printing significantly lowers the barrier to entry in aerospace engineering, making it feasible for smaller firms and startups to innovate and contribute to the industry. The reduced cost of prototyping and manufacturing allows for greater experimentation and innovation.

💡 Customization and Flexibility

The technology affords unprecedented levels of customization, enabling engineers to tailor components specifically to their needs without the constraints of traditional manufacturing techniques. This flexibility opens up new possibilities in design and functionality.

🌐 Sustainability and Environment

With additive manufacturing, material waste is drastically reduced, contributing to more sustainable production processes. Additionally, the ability to produce parts on demand can lower the carbon footprint associated with transportation and storage.

The Future: Beyond the Horizon

🛰 New Materials, New Possibilities

Research into new materials suitable for 3D printing is ongoing, with the promise of creating components that are lighter, stronger, and more adaptable to the harsh conditions of space.

🌌 Fully Printed Rockets and Spacecraft

The prospect of fully 3D-printed rockets and spacecraft is no longer a distant dream. Companies like Relativity Space are already working towards rockets made almost entirely from printed parts, aiming to revolutionize how we access space.

🤖 Automation and AI Integration

The integration of AI with 3D printing promises to further streamline the design and manufacturing process, enabling real-time adjustments and optimizations that could significantly enhance performance and efficiency.

Conclusion: A Universe of Potential

The intersection of 3D printing and aerospace engineering is a testament to human ingenuity and a beacon for future innovation. As Lyon Industries continues to explore this fascinating frontier, the potential for discovery and advancement seems as boundless as the universe itself. With each layer printed, we come one step closer to a future where the sky is not the limit but just the beginning.

Lyon Industries is committed to advancing the frontiers of aerospace and rocketry through innovative research and development. Join us as we journey through the cosmos, powered by 3D printing and additive manufacturing.