3D Printing Structural Members in Deep Space.

Abstract

This comprehensive exploration delves into the innovative application of 3D printing technology for constructing structural members directly in the vacuum of space. Utilizing carbon fiber filaments, this pioneering approach introduces a satellite-based system capable of producing elongated, robust structural elements in situ. This method significantly reduces the logistical and financial burdens traditionally associated with transporting construction materials from Earth to space. The implications of this technology extend to the development of extensive-scale habitats, protective shields against micro-meteoroids, and other critical infrastructures in orbit. Through an in-depth examination of the technology, its advantages, potential challenges, and future directions, this paper highlights the transformative potential of in situ 3D printing for space exploration and colonization.

Introduction

The ambition to extend human presence beyond Earth presents unique engineering and logistical challenges, particularly in constructing and maintaining off-world habitats and infrastructure. Traditional methods, reliant on the costly and constrained transport of materials from Earth, face significant limitations due to the payload capacities of current launch systems. In response, the concept of in situ resource utilization (ISRU)—the practice of harvesting and processing materials directly in space—has emerged as a promising solution to these challenges. Among ISRU technologies, 3D printing stands out for its ability to create complex structures with minimal waste and reduced need for human labor. This white paper focuses on a revolutionary 3D printing approach that leverages carbon fiber filaments, offering a leap forward in constructing space infrastructure efficiently and sustainably.

Technology Overview

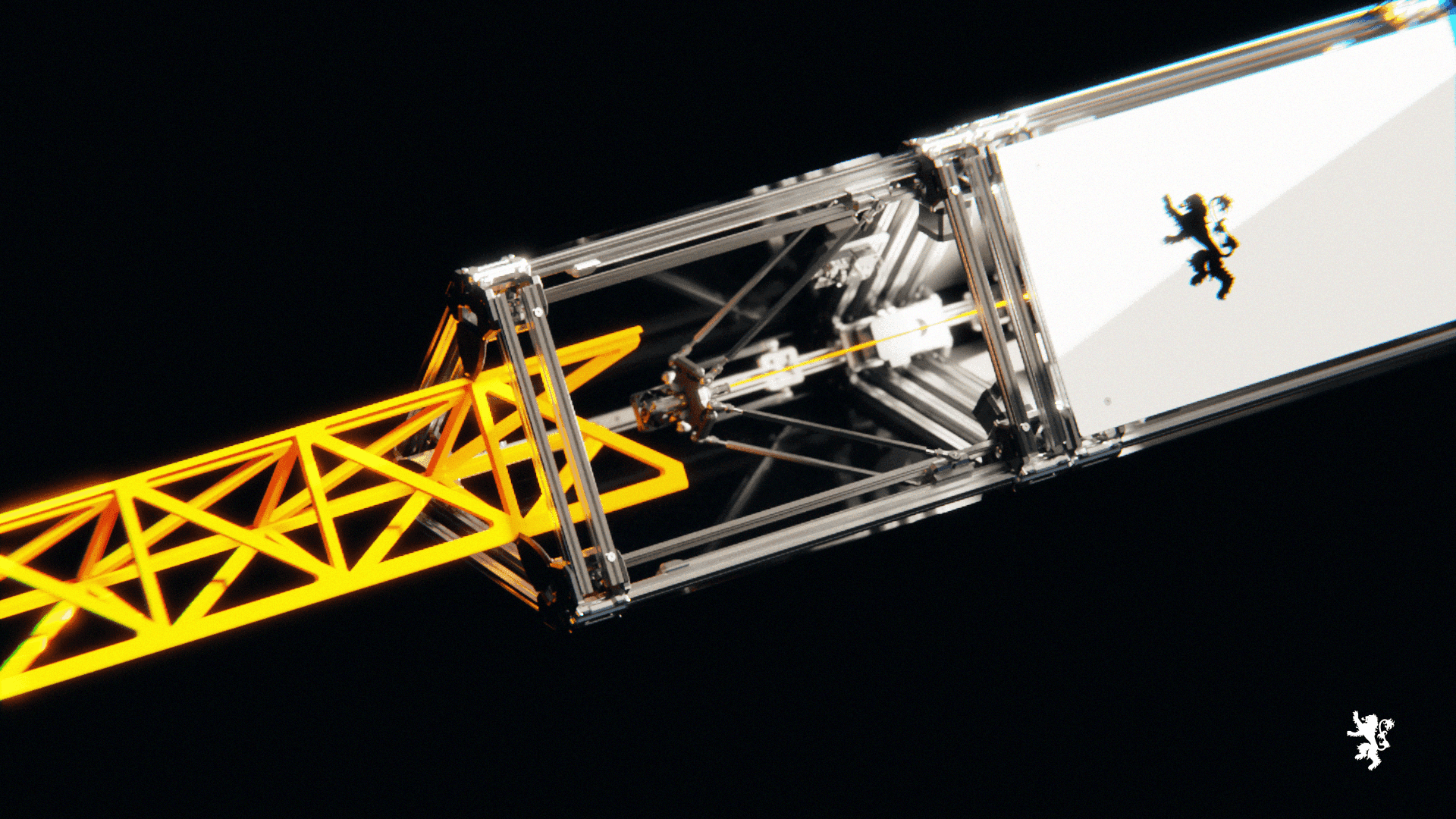

The core of this innovative technology is a satellite equipped with a sophisticated 3D printing apparatus, designed for the autonomous production of structural members in the vacuum of space. The system uses carbon fiber filament, chosen for its superior strength-to-weight ratio and resilience to space's harsh conditions. A specialized three-arm jig and extrusion housing ensure precise and stable extrusion, critical for achieving structural integrity in the absence of gravity.

Carbon Fiber Filament

Carbon fiber's exceptional properties make it an ideal material for space construction. Its application in this technology represents a significant advancement over traditional space construction materials, providing unparalleled strength, durability, and resistance to thermal and radiation effects in space.

Three-Arm Jig and Extrusion Housing

The printing process is supported by a three-arm jig, which stabilizes the structure during extrusion, and an extrusion housing, designed to function in the vacuum of space. This setup allows for the production of structural members with consistent quality and integrity, essential for the safety and durability of space structures.

Advantages

The application of this technology offers several groundbreaking advantages:

- Cost-Effectiveness: By drastically reducing the need to transport materials from Earth, this approach offers significant cost savings on construction projects in space.

- Scalability: The ability to produce structural members of virtually any length enables the construction of large-scale structures that would be impractical to launch from Earth.

- Material Efficiency: The use of carbon fiber filament minimizes waste, as materials can be precisely extruded according to the needs of the construction project.

- Versatility: This technology paves the way for constructing a wide variety of structures, from habitats and laboratories to shielding against space debris.

Case Studies

(Placeholder for hypothetical scenarios or references to past experiments that demonstrate the technology's potential.)

Challenges and Limitations

While the promise of this technology is vast, several challenges remain to be addressed, including the reliability of long-duration autonomous operations in space, the precision of construction in microgravity environments, and the need for extensive testing to ensure the structural integrity of printed elements.

Future Directions

The ongoing development of this technology opens exciting prospects for space exploration and colonization. Future advancements may include the integration of multi-material printing capabilities, the utilization of resources harvested from asteroids or lunar soil, and the construction of complex, self-sustaining habitats.

Conclusion

The development of 3D printing technology for constructing structural members in space represents a significant leap forward in humanity's quest to explore and inhabit the cosmos. By addressing the logistical and financial challenges of space construction, this technology stands at the forefront of enabling the sustainable expansion of human presence beyond Earth.

References

(Placeholder for references to scientific articles, patents, and other relevant literature.)